IOT Based Coal Mining Safety Using Nodemcu

Call for Price

The most advantage of this project is that IoT detects the uncertainty within the setting beforehand victimization information analysis reports things to the involved authority and also the miners. The system conjointly considers the emergency things in hand to alert the miners as quickly as attainable.

Shipping: 4 to 8 working days from the date of purchase

Package Includes:

-

Complete Hardware Kit

-

Demo Video-Embedded Below

-

Abstract

-

Reference Paper

-

PPT (20 Slides)

-

!!! Online Support !!!

Description

Abstract

Now a day’s because of heating and climate changes there are difficult things within the field of a coal pit. To scale back the value and improve the productivity beside product quality the atomization within the field of a coal pit is so necessary, which can additionally scale back the mine staff efforts. This paper proposes a style of a wireless detector network (WSN) with the assistance of the Nodemcu esp8266 controller that is in a position to observe the temperature, humidity, gas, and standing of smoke in associate degree underground mine. This method additionally controls the ventilation demand to mine staff relying upon gift climate conditions inside the piece of land. This method utilizes low power, efficient Nodemcu esp8266, a temperature detector LM35, wetness detector SYSH220, smoke detector, the gas detector for sensing the mine climate parameters and Wi-Fi for remote work of information at a central location management to regulate to manage the climate state with the assistance of motor and valve control electronic equipment. Traditional coal pit watching systems tend to be wired network systems, which play a very important role in coal pit safe production. With continuous enlarging of exploiting areas and extension of depth during a coal pit, several laneways become blind areas, whereby there are unit uncountable hidden dangers. Moreover, it’s inconvenient to put cables that area unit costly and consume time. so as to resolve the issues, we’ll style a coal pit safety watching system supported wireless detector network, which may improve the extent of watching production safety and scale back accident within the coal mines Wireless detector networks area unit composed of an oversized variety of micro-sensor nodes that have tiny volume and low price.

Introduction

Underground mining operations prove to be a risky venture as far as the safety and health of workers are concerned. These risks are due to the different techniques used for extracting different minerals. The deeper the mine, the greater is the risk. These safety issues are of grave concern especially in the case of coal industries. Thus, the safety of workers should always be of major consideration in any form of mining, whether it is coal or any other mineral. Underground coal mining involves the next risk than open pit mining thanks to the issues of ventilation and potential for collapse. However, the utilization of heavy machinery and the methods performed during excavations result in safety risks in all types of mining. Modern mines often implement several safety procedures, education, and training for workers, health and safety standards, which lead to substantial changes and improvements and safety levels both in opencast and underground mining.

Proposed System

The planned system consists of the device modules that since all the information around the mine setting and logs the information onto the cloud controlled server page the IOT module. The sever page is maintained IOT module. The logged information is processed into the common values for every entry on an associate interval basis. These prices area unit mechanically processed employing a predefined value maintained by the server page. Once there’s associate absolute modification within the values of the perceived information associate alert is shipped to the IOT MODULE and also the involved authorities. The IOT module detects the alert signal and glows the intrinsic device and alert messages to the authorities could take precaution steps. The most advantage of this project is that IoT detects the uncertainty within the setting beforehand victimization information analysis reports things to the involved authority and also the miners. The system conjointly considers the emergency things in hand to alert the miners as quickly as attainable.

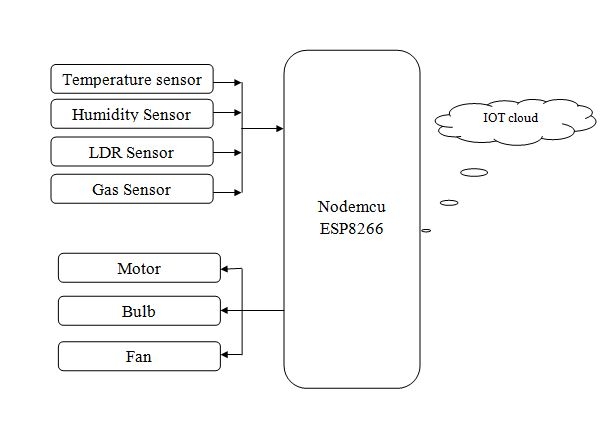

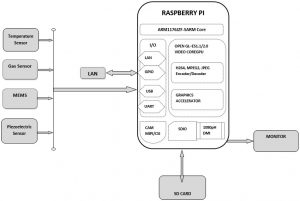

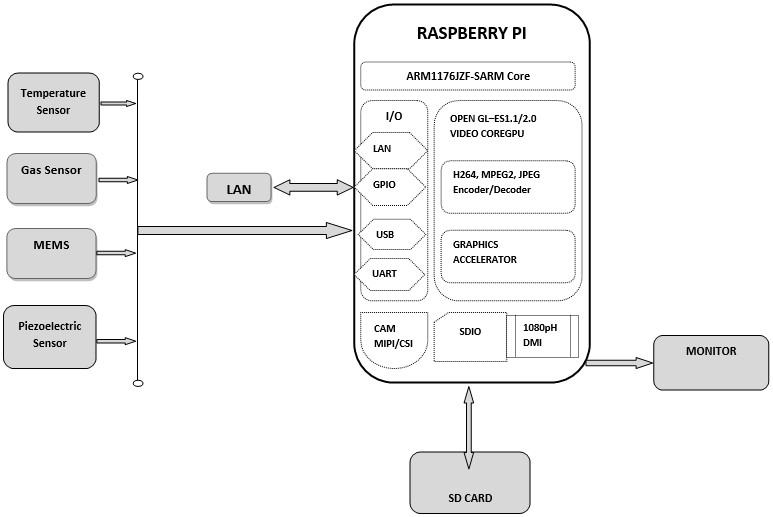

Block Diagram

Block Diagram Description

The Temperature sensor is used to measure the mine temperature and humidity sensor measures the humidity level in mining time. The gas sensor is using to find them gas level in mining and the LDR sensor is used to find the light density and if any abnormal value means the microcontroller will send each second value to IOT cloud and electrical devices upon the sensor value. all sensor value is uploaded to the IOt cloud in this method.

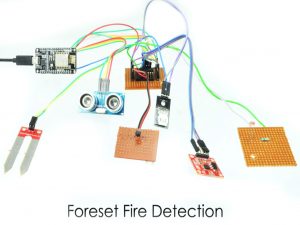

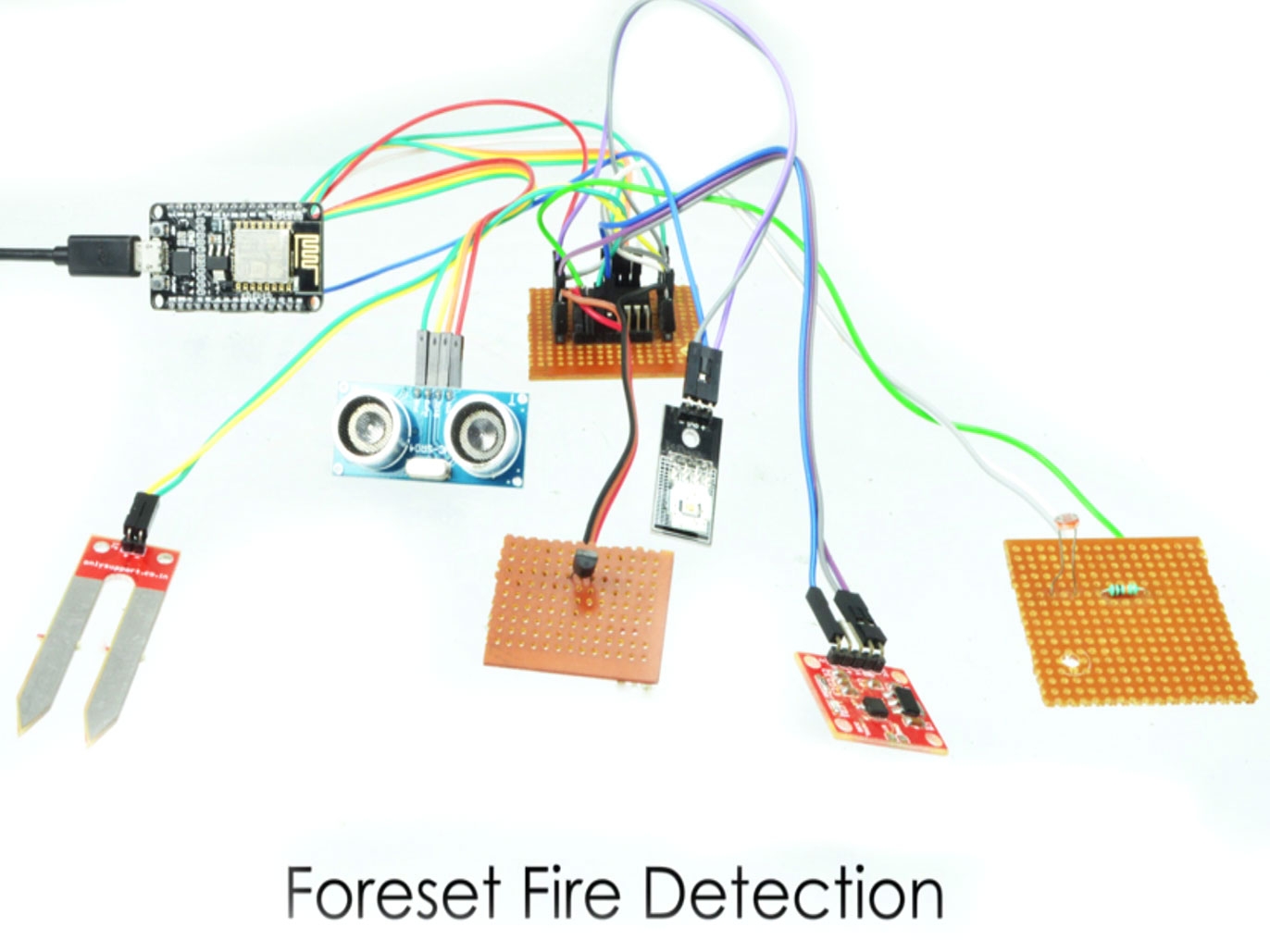

Hardware

- Nodemcu esp8266

- LDR sensor

- LM35 sensor

- humidity sensor

- Gas sensor

- Fan

- Motor

- Bulb

Software

- Arduino IDE

Conclusion

The study on real-time monitoring of toxic gases and other parameters present in underground mine has analyzed using wireless sensor networks. A real-time monitoring system is developed to provide clearer and more point to point perspective of the underground mine. This system is displaying the parameters on the serial monitor at the underground section where sensor unit is installed as well as on the monitoring unit; it will be helpful to all miners present inside the mine to save their life before any casualty occurs. Alarm triggers when sensor values cross the threshold level. This system also stores all the data in the IOT cloud.

Additional information

| Weight | 1.000000 kg |

|---|

Reviews

There are no reviews yet.