Defect Detection of PCB Fabrication with Subtraction Method using Spartan3 Image Processing Kit

Call for Price

It is inevitable that there will appear defections such as the appearance not neat, solder mask unevenness, lines and pads damages in the production of printed circuit board. In this Project Spartan3 FPGA Image Processing Kit based image acquisition system of the circuit board is designed.

Shipping : 4 to 6 working days from the Date of purchase

Package Includes:

-

Complete Hardware Kit

-

Demo Video-Embedded Below

-

Abstract

-

Reference Paper

-

!!! Online Support !!!

Description

Abstract

It is inevitable that there will appear defections such as the appearance not neat, solder mask unevenness, lines and pads damages in the production of printed circuit board. In this Project Spartan3 FPGA Image Processing Kit based image acquisition system of the circuit board is designed. Digital image processing technology has been carried on the analysis of the collected image. In image preprocessing, these processing methods as image enhancement, edge detection, the two value processing method have been used to improve the image quality. In the extraction and recognition of the defection, subtraction method is used to perform the detection of the defect board through the comparison and matching of the defect image and the template image.

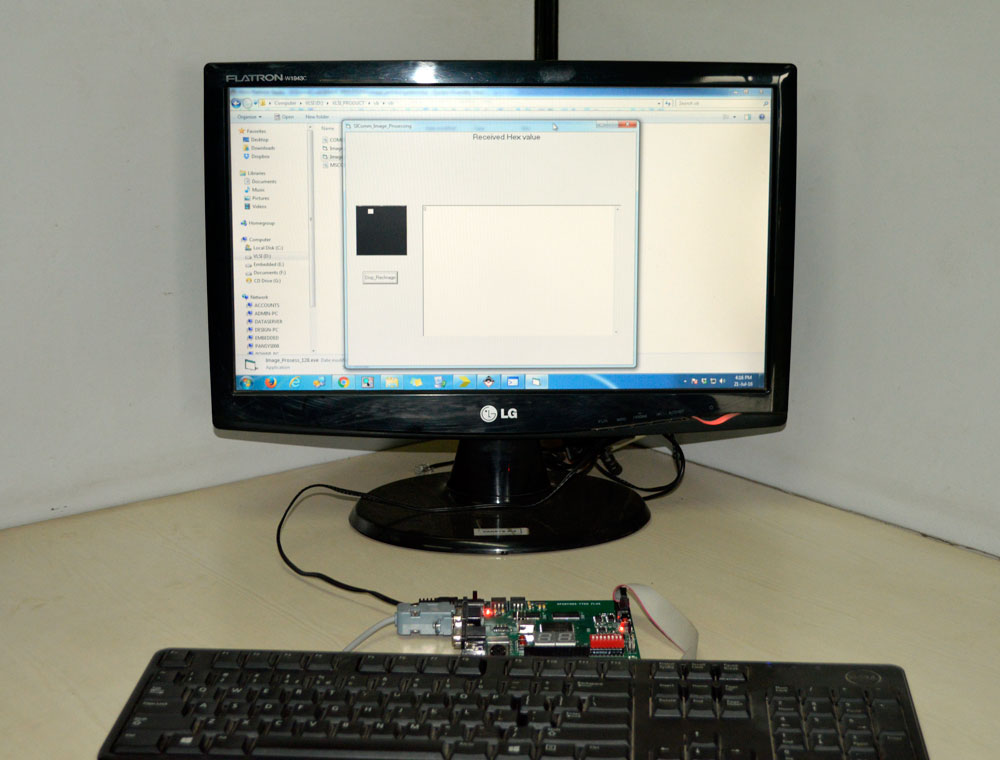

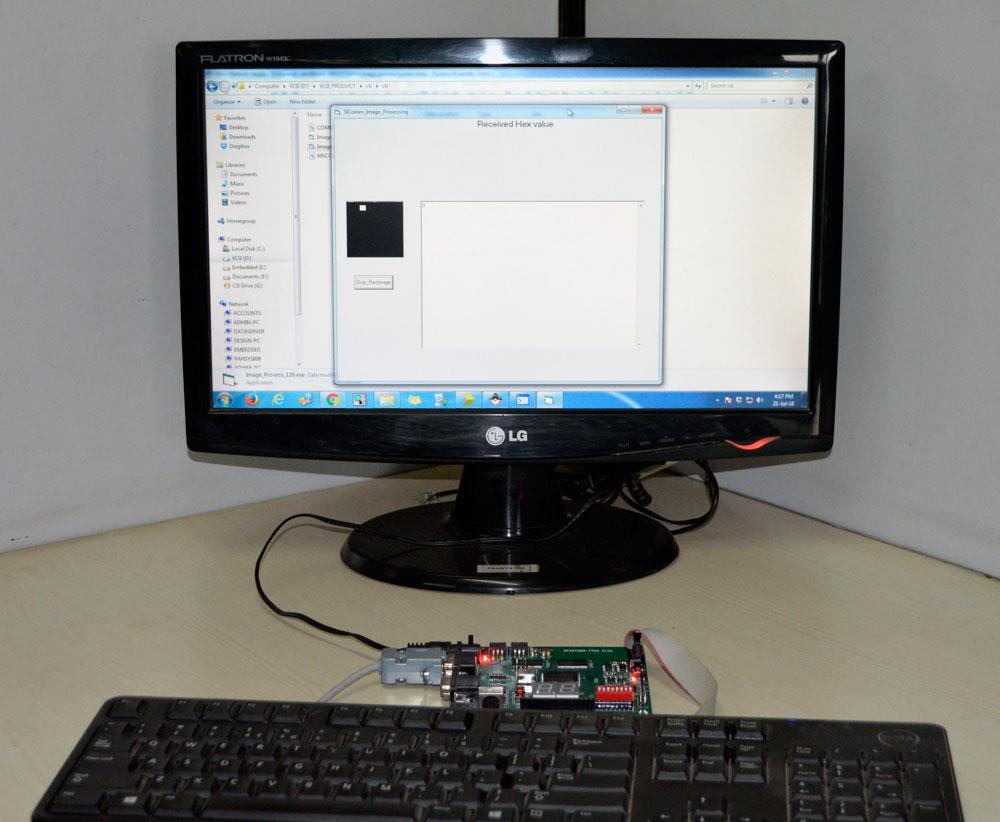

Demonstration Video

Software:

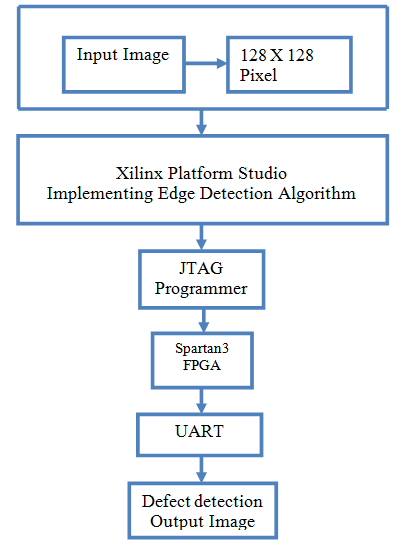

- Xilinx ISE 11.1i or above

- Xilinx EDK 11.1i or above

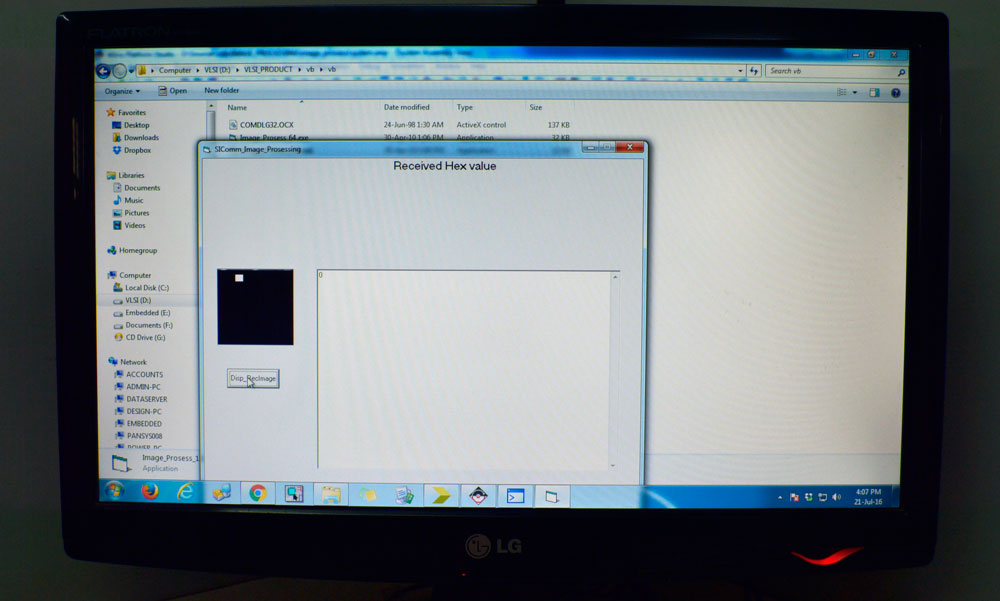

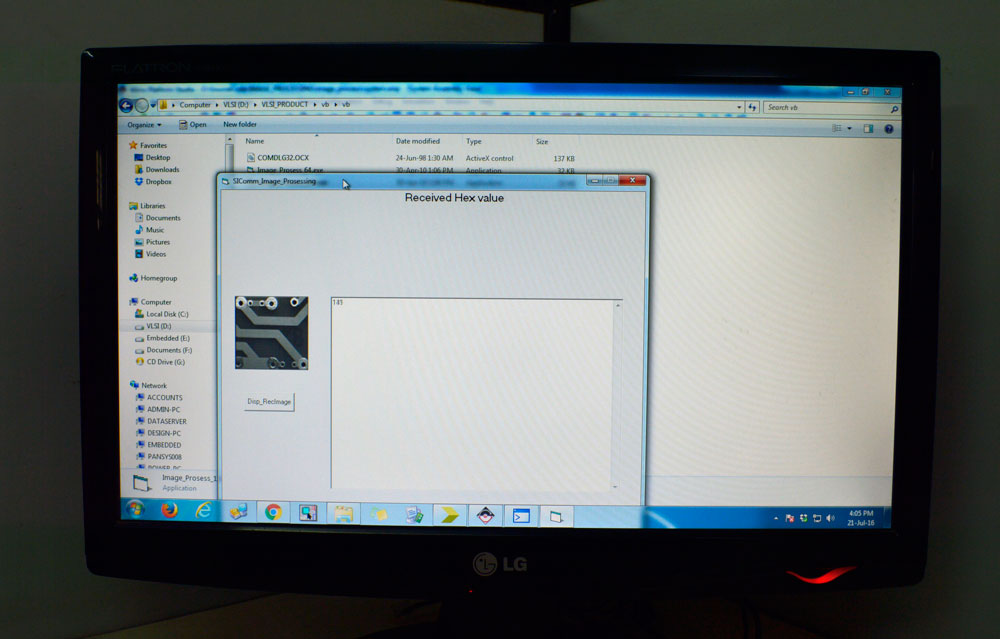

- VB GUI to display output

Language:

- VHDL, System C

Hardware:

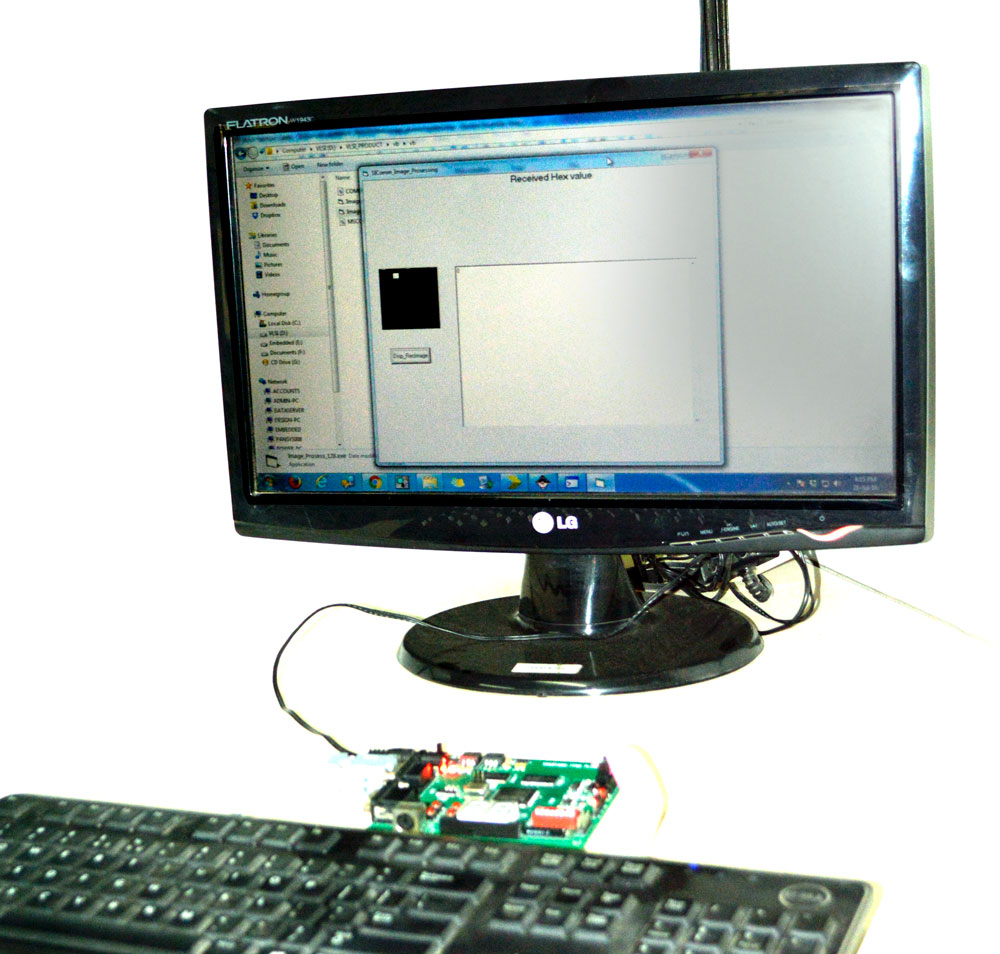

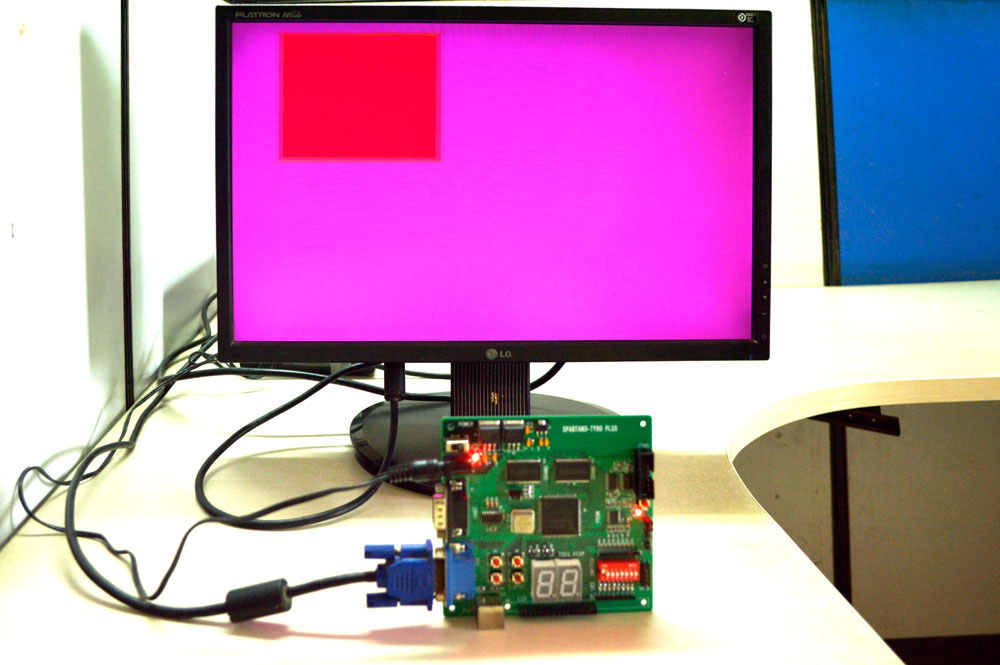

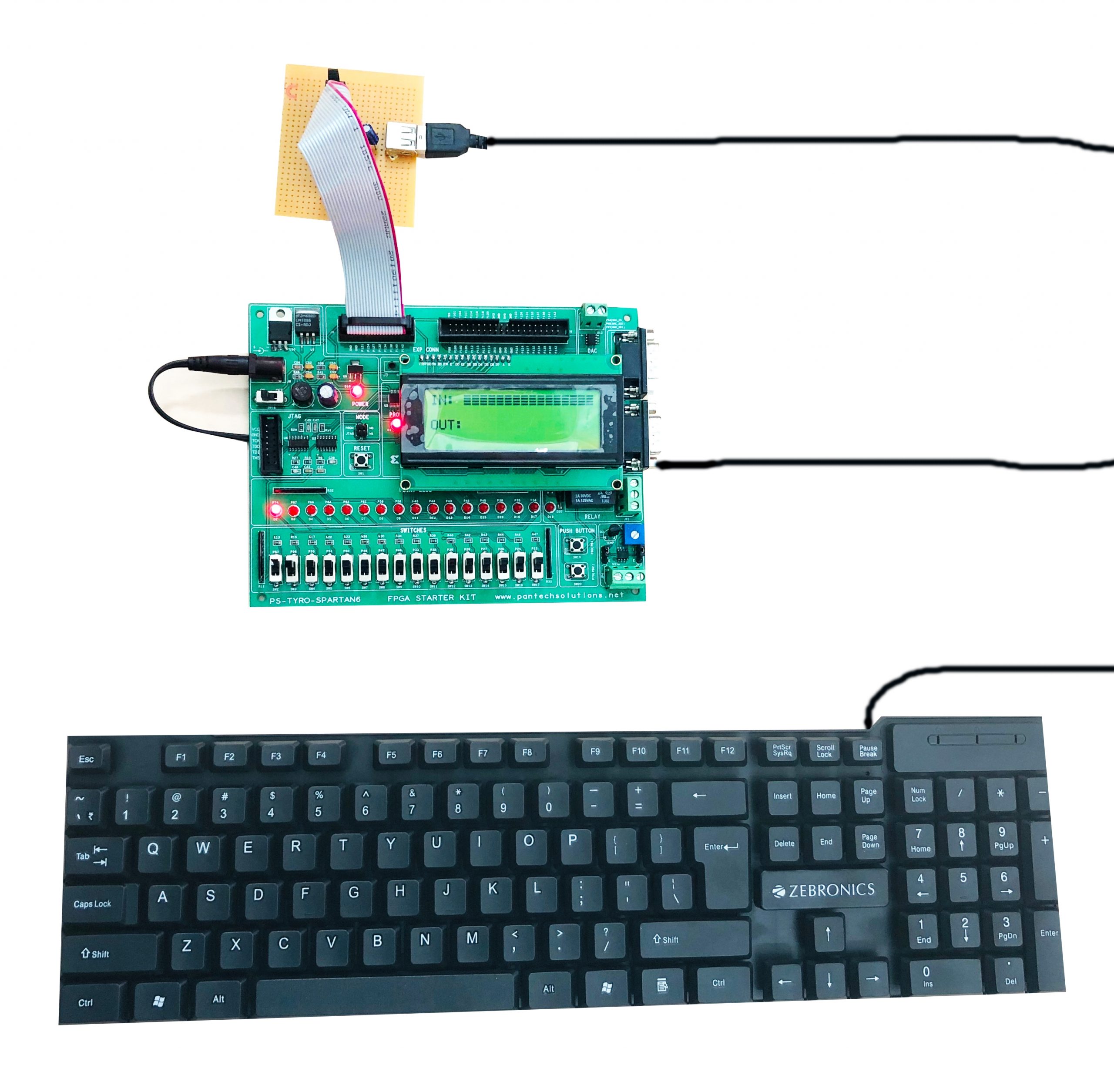

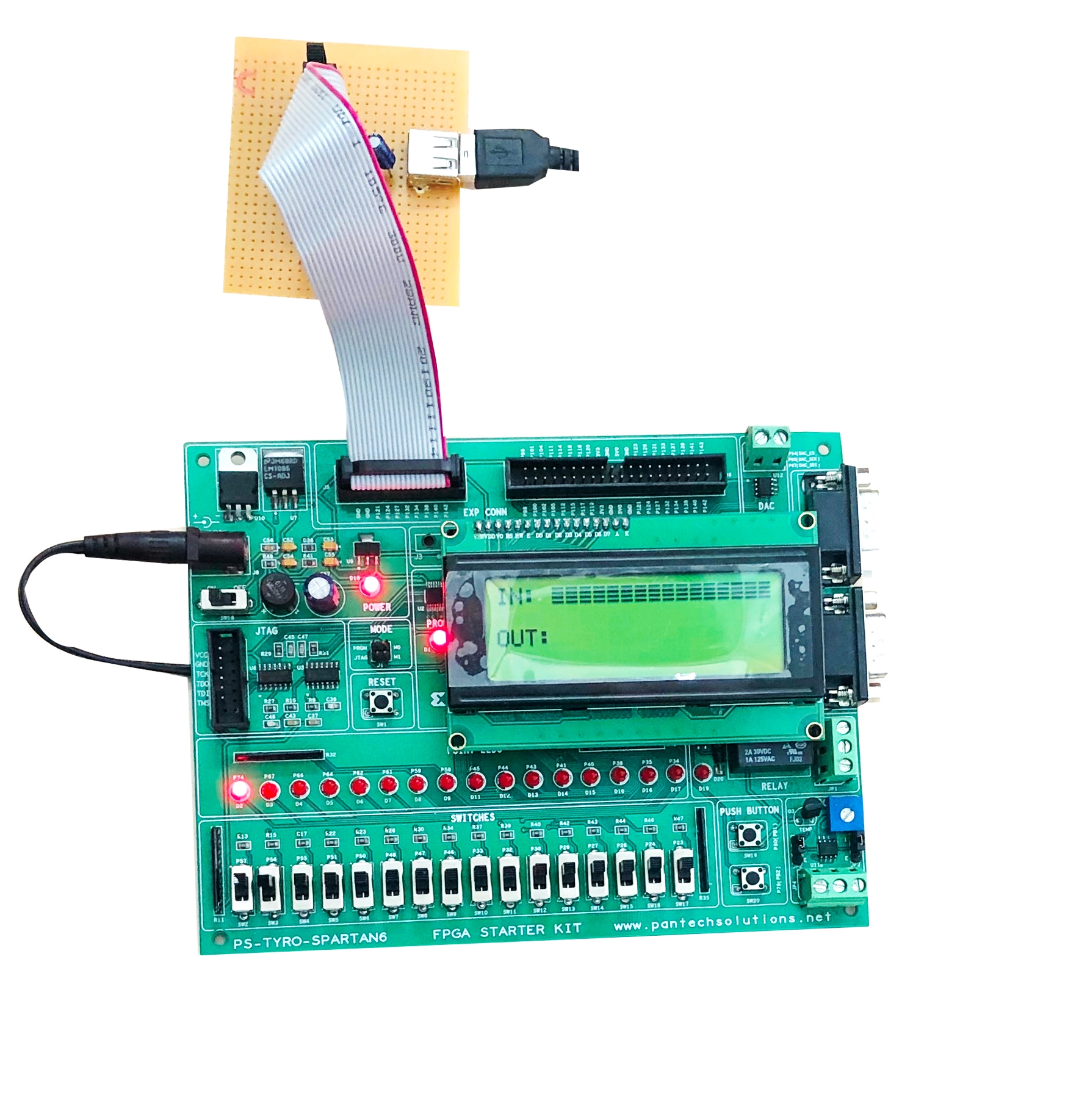

- Spartan3 FPGA Image Processing Kit

- JTAG Cable

- PC

- Serial Cable

Block Diagram for Defect Detection of PCB Fabrication with Subtraction Method using Spartan3 FPGA Processing Kit

Introduction:

The quality of modern electronic equipment relies not only on the electronic components’ quality and performance, and depends on the quality of printed circuit board to a great extent. It is inevitable that there will appear defections such as the appearance’s not neat, solder mask’s unevenness, lines’ and pads’ damages in the production of printed circuit board. Online detection is a necessary segment to ensure the quality of circuit board.

In this project the detection system to the final board is introduced, which is significant to guarantee the production quality. Electrical and optical detections are the two kinds of quality inspections of printed circuit board. And visual detection technology based on image processing has been becoming one of the hot researching aspects with the advantages of non-contact, fast speed, appropriate precision, strong ability of anti interference.

The image visual inspection system for printed circuit board can recognize those defections as bad welding point, even for solder, copper and platinum breaking point, short circuit etc. through the digital image processing and recognition technology. Image processing has two purposes, one is to generate images more suitable for human observation and identification, the other is to recognize and understand images automatically. The system includes image acquisition system, image enhancement, edge detection, defect detection. We try to use subtraction method to perform defect detection of printed circuit boards. The system is aimed to facilitate the actual operations which can provide a basis for the online, fast and accurate detection of printed circuit boards.

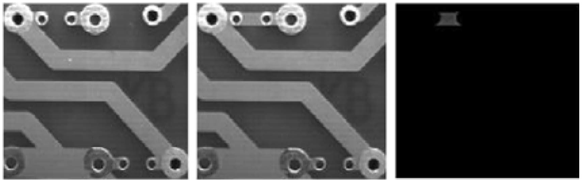

Defect Detection of PCB using Subtraction Method

Background subtraction can provide the difference between images and can be used to guide the dynamic monitoring, moving target detection and tracking, image background elimination and image recognition etc. It must make the image corresponding to the same target point, or geometric correction and matching must be first done. In the processing noise will be extracted and leaving only defect characteristics so as to achieve the purpose of identification and classification.

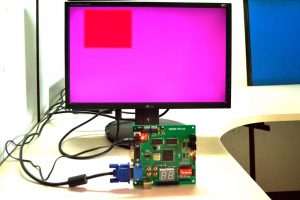

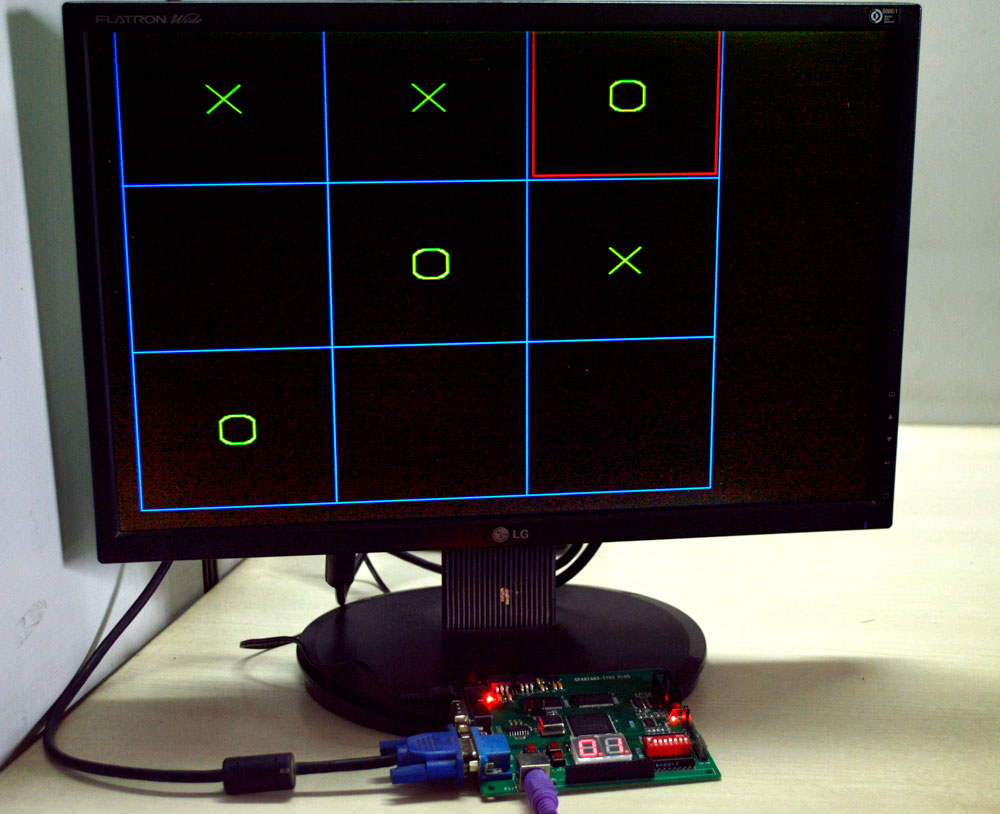

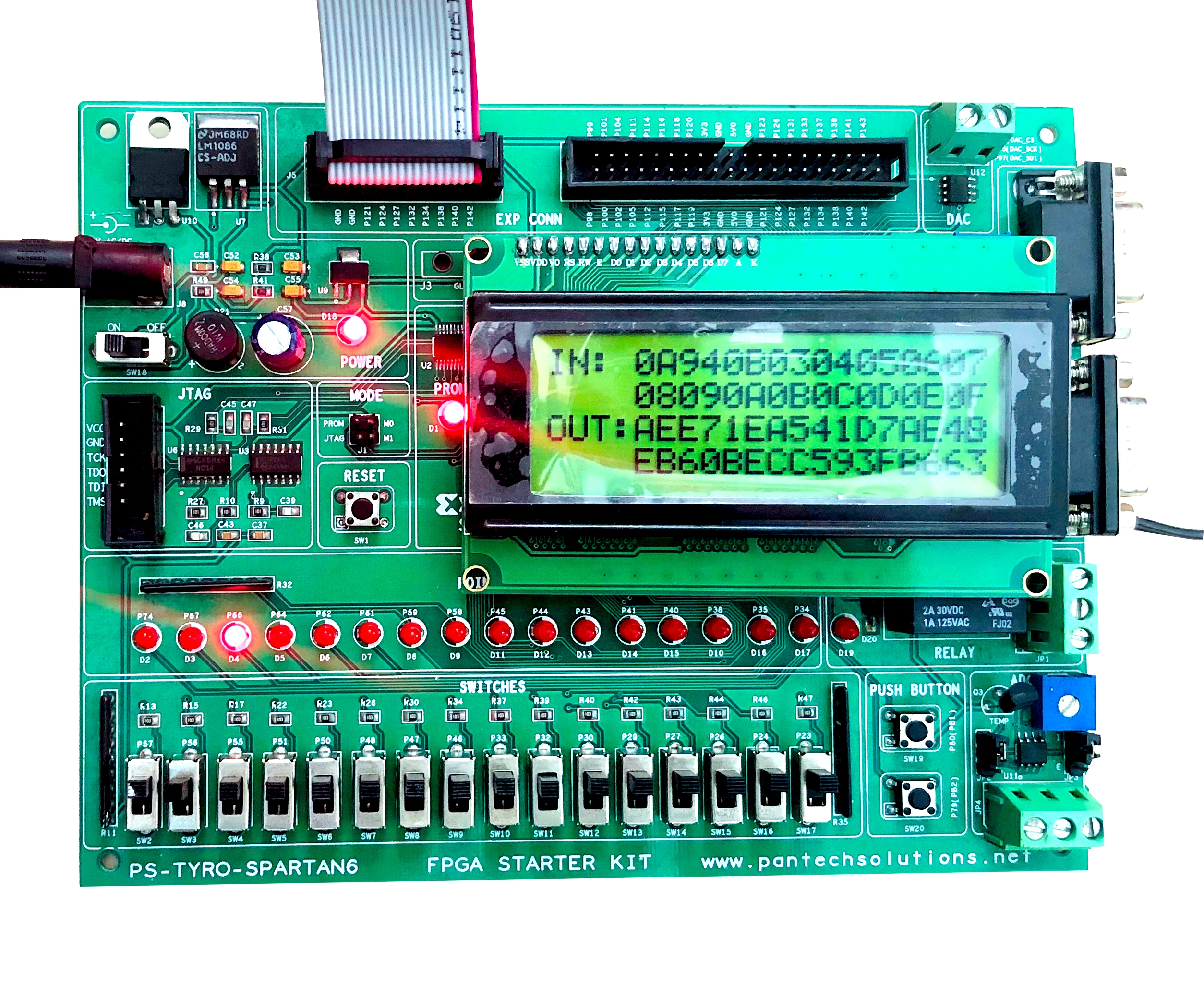

Output Image of Defect detection using Spartan3 FPGA Processing Kit

Defult Detection Output Image

Conclusion

The Spartan3 FPGA Image Processing Kit implementation of Defect Detection of PCB with Subtraction Method meets the real-time requirements. This architecture based on FPGA is much better than processing images on software platform.

Additional information

| Weight | 1.000000 kg |

|---|

Reviews

There are no reviews yet.