DC position control system using PID

Call for Price

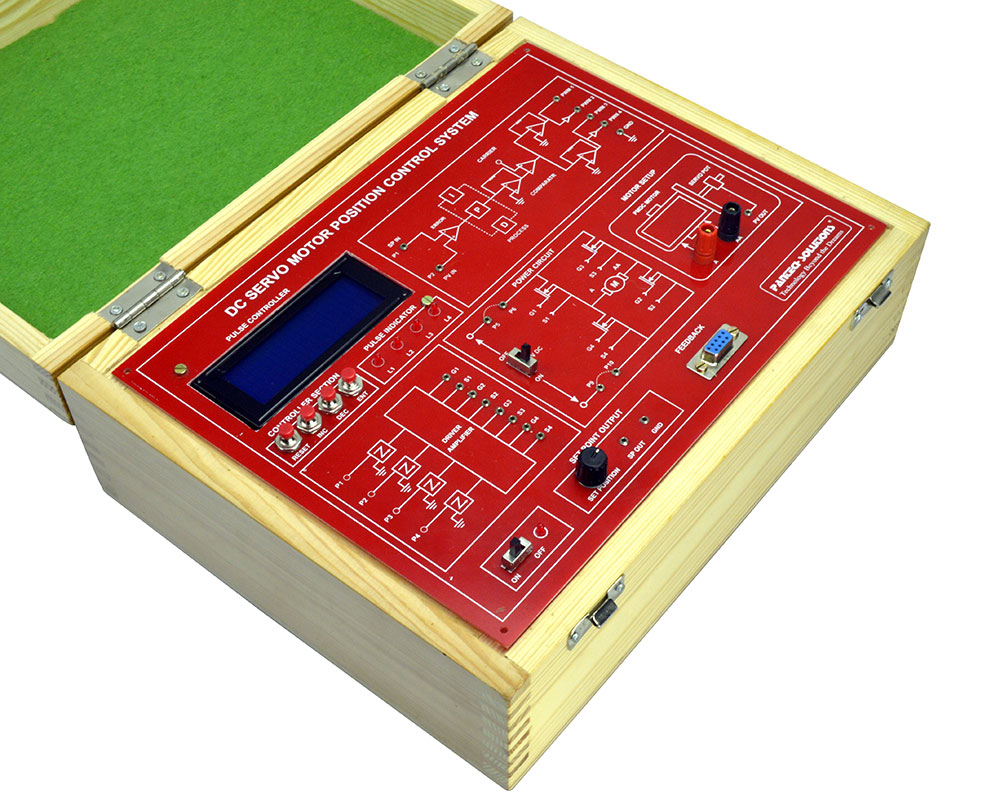

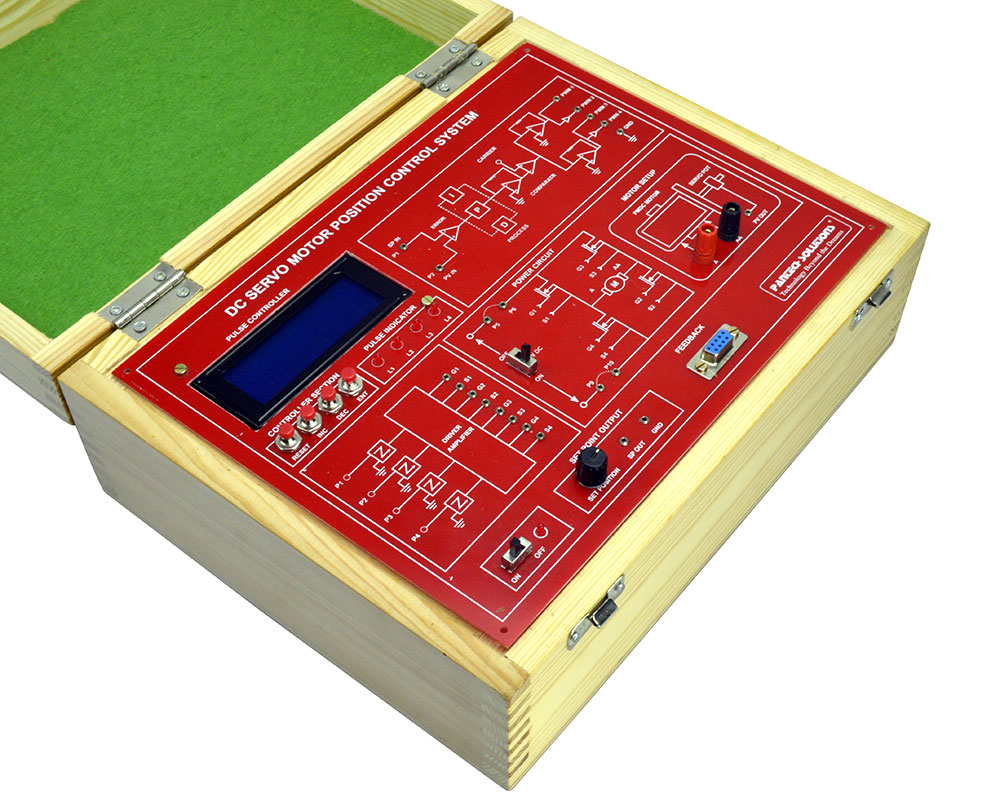

Dc position control system using PID

Description

Description

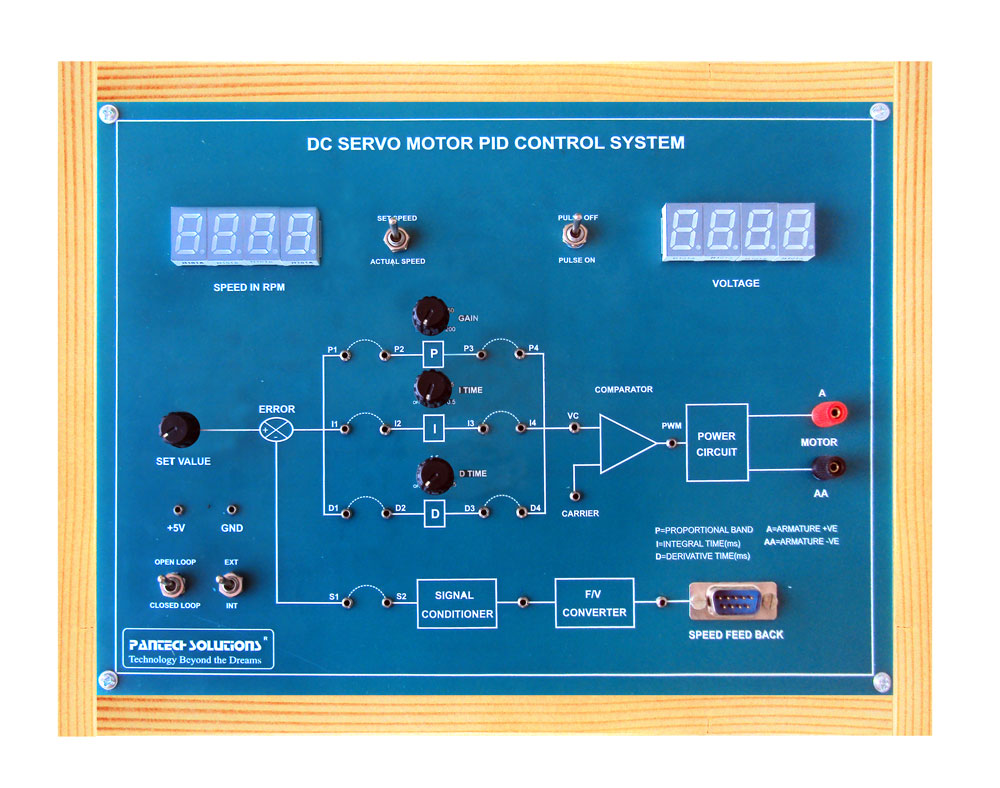

The motors that are used in automatic control systems are called Servomotors. When the objective of the system is to control the position of an object then the system is called servo mechanism. The servomechanism is a feedback control system in which the output is mechanical position.

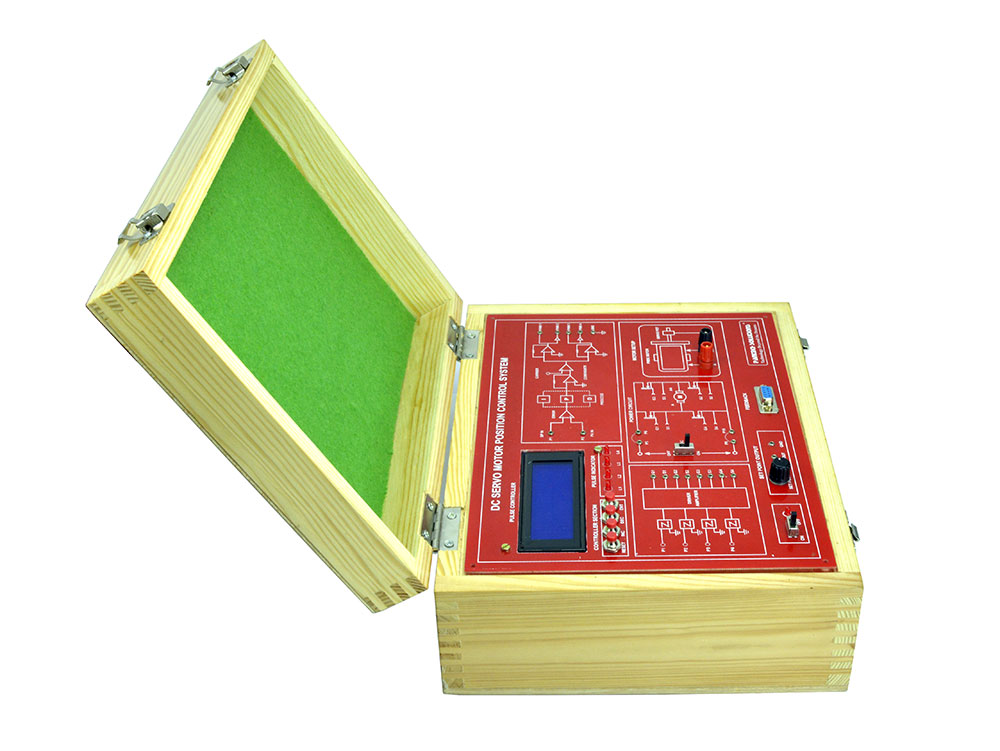

Pantech Solutions has designed dc position control system trainer module to perform DC position control. This module consists of a high performance Permanent Magnet DC Motor, often with an integral and a chopper based power circuit.

Features

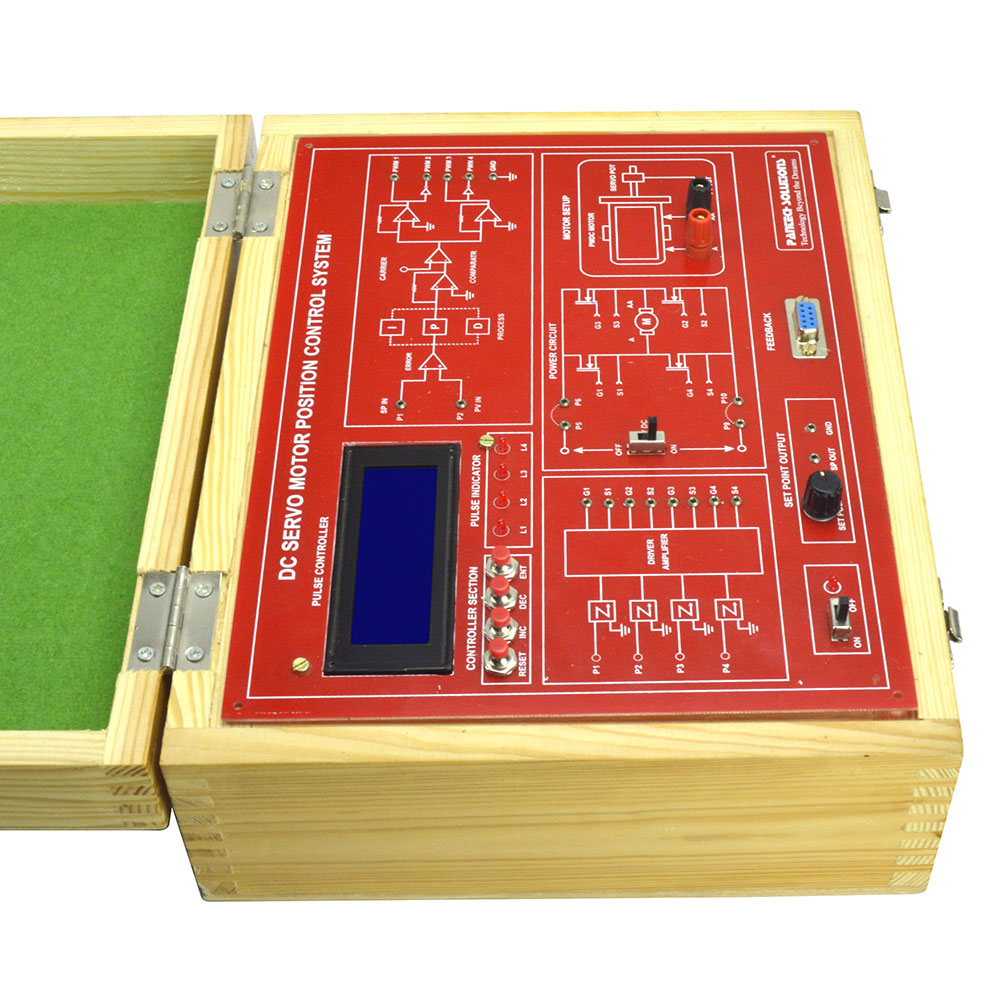

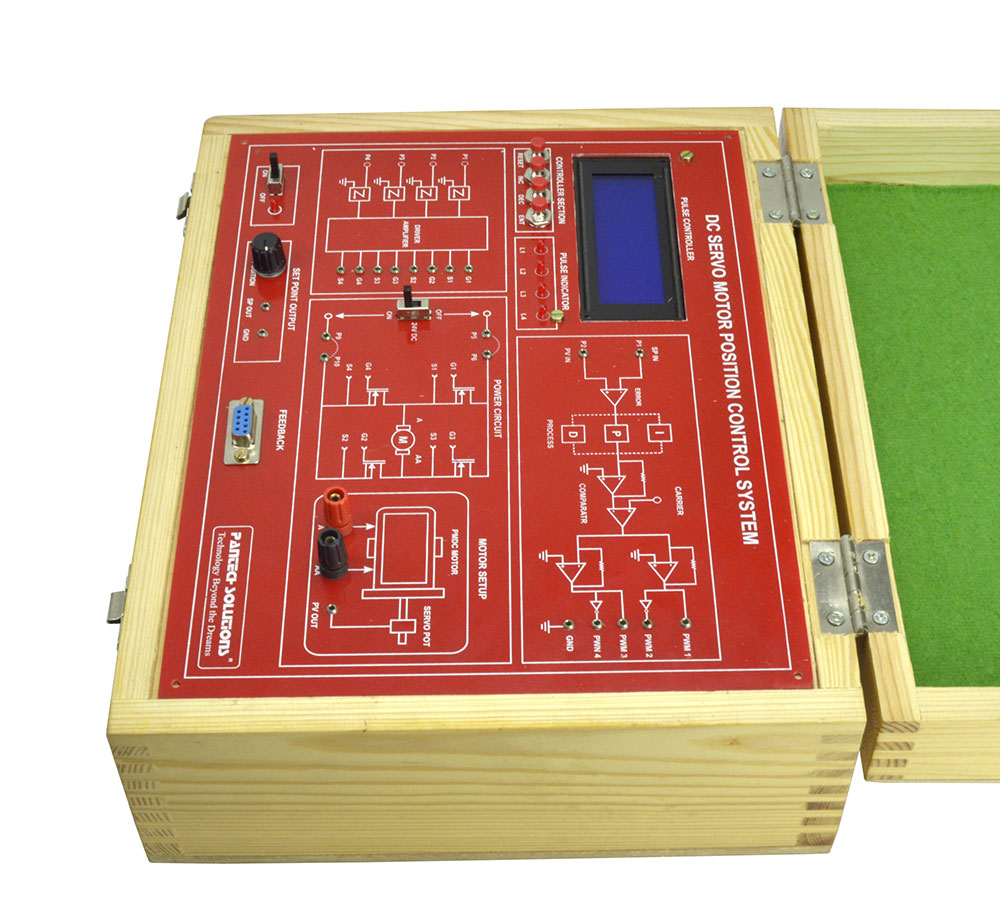

- 4 Quadrant MOSFET chopper provided for forward & reverse direction

- MOSFET driver provided

- One Op-Amp PI Controller for control circuit

- One 20/4 LCD display to indicate the set position and actual position in degree (0-355º)

- One potentiometer is provided to vary the motor position up to 355º

- +15V DC&-15VDC, for control circuit, 24V DC for Power Circuit

Mechanical Setup

- One PMDC 24 volt with Gear provided

- Motor speed 1500rpm

- Gear ratio 30: 1 to run 50rpm speed

- One Servo potentiometer provided at the low speed shaft for position setting.

Experiments

- Study the position sensor (Servopot).

- Study the DC servomotor position controller with P controller.

- Study the DC servomotor position controller with PI controller.

- Study the DC servomotor position controller with PID controller.

Technical Specification

- Kit Working voltage : (220-240)VAC

- Input Voltage : 24V AC

- Input Frequency : 50Hz

- Output Voltage : 0 TO 24V DC

- Output Current : 1Amps

Bundle Contents

- Dc position control system

- Patch cards

- 6A power supply card

- 1A Fuse

- Manual

Additional information

| Weight | 1.000000 kg |

|---|

Reviews

There are no reviews yet.