A CAN Bus Based System For Monitoring And Fault Diagnosis In Wind Turbine

Call for Price

A CAN Bus Based System For Monitoring And Fault Diagnosis In Wind Turbine

Description

ABSTRACT

This paper is a CAN based architecture designed for the purpose of monitoring and fault diagnosis of wind turbine. CAN is a Message based protocol designed specifically for Automotive, later Aerospace, Industrial automation and Medical equipment’s. CAN interface module is used to communicate the monitored parameters between the wind turbine and the control center. During the transmission of the data from one node to another node disturbance occurs. To avoid these disturbances we propose CAN protocol.

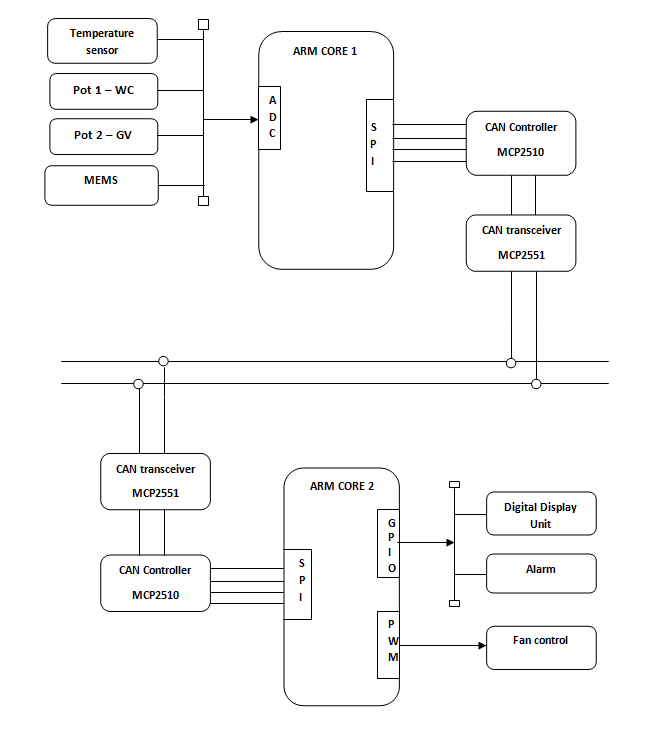

In this project we declare the system with ARM and CAN protocol to monitor and diagnose the problems in the wind turbine application. The project deals with the data transmission between two units in the exact time without any disturbance. The data transmission time is increased with the CAN protocol. ARM core1 runs with CAN and LPC2148 as wind turbine unit to which sensors are connected and ARM core2 as Fault diagnose and monitoring section. A discussion about weather condition (WC) monitoring and generation voltage (GV) display is also added in this design. Data acquisition node collects the sensor data through CAN protocol. The basic view of this technique is to reduce the possibility of fault diagnosis and increase the monitoring of wind turbine.

EXISTING SYSTEM

- Manual operation.

- Automatic turbine power ON/OFF control

- No indication

PROPOSED SYSTEM

- High Speed Communication Protocol (CAN)

- Turbine rotation speed measurement

- Temperature based fan controller

- Data acquisition unit in monitoring section

- Vibration detection

BLOCK DIAGRAM

Wind Turbine unit and Fault diagnosis unit

HARDWARE REQUIREMENTS

- ARM LPC2148

- MEMS Accelerometer

- Potentiometer

- Temperature sensor

- IR RPM counter

- CAN controller MCP2510

SOFTWARE REQUIREMENTS

- Compiler (KEIL IDE)

- Orcad design

- Programmers (Flash Magic)

- Languages: Embedded C

APPLICATIONS

- Electrical applications

- Industrial applications

DEMO VIDEO

Additional information

| Weight | 1.000000 kg |

|---|

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Related products

-

- Read more

- ARM7 Projects

Using A CAN Bus For Control Of An All-Terrain Vehicle

- Call for Price

- Rated 0 out of 5

-

- Out of StockRead more

- ARM7 Projects

ARM-7 Intelligent Power plug using GSM

- Call for Price

- Rated 0 out of 5

-

-

- Read more

- ARM7 Projects

Obstacle Avoidance Based On Fuzzy Controller And Ultrasonic Sensors using ARM

- Call for Price

- Rated 0 out of 5

Reviews

There are no reviews yet.